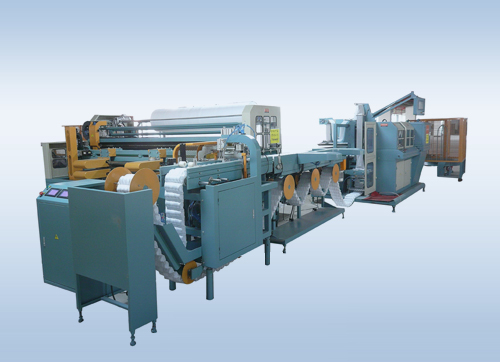

pocket Spring Unit Auto-transfer production line

Technical characteristics:

· Two electronically controlled coiling heads

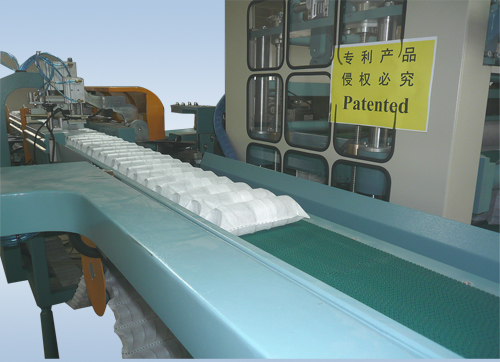

· Independent ultrasonic cutting device for pocket spring strings.

· Smart conveyor for pocket spring strings

· Shock-proof and interference-proof system for electronic components.

· Accurate servo spring conveyor system.

· Intelligently automatic alarm system.

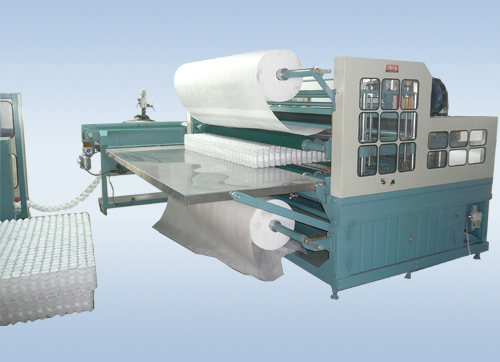

· Flexible heat treatment device.

· Smart joint device for non-woven fabric roll.

· Various customized ultrasonic welding seam .

· Only one operator is required

Model 1: HS-2PSM80-L-1SAM75

· Two electronically controlled coiling heads.

· Computerized spring dimension setting system.

· Computerized various spring data saving system.

Special Option, if desired:

· Zoning pocket spring is possible with two different steel wires.

· Available for springs in hour-glass shape, pyramid shape, PPS type and so on.

Option 2: HS-2PSM80-L-1SAM75

· Two mechanical coiling heads.

|